A glass-making oven has been a helpful tool when it comes to glass-making. The majority of the glass-making industry has been reliant on it.

The glass-making oven is a type of furnace that is used to melt and even anneal glass. Annealing is a process where glass is toughened through heating and slowly cooling after.

It is almost impossible to find a glass-making facility without a glass-making oven. It is a necessary and crucial tool for glass-making facilities.

There are also many ways of utilizing a glass-making oven. The techniques are essential as well because a wrong move can affect the whole structure of the glass.

The good thing is that glass-making ovens are not difficult to maintain. Still, its users have to be careful around it.

Above-average temperatures surround a typical glass-making oven. It has an average temperature of 1350 degrees Celsius or 2462 Fahrenheit.

That is why experts or knowledgeable individuals handle these things. Ordinary individuals are most likely not permitted to operate a glass-making oven because of the hazards it may cause.

Contents

What is a Glass Making Oven?

A glass-making oven is also called a glass furnace. Some individuals call it ‘lehr.’

Glasses and steel are an example of materials for the annealing process. However, unlike steel, glass manufacturing is specifically for glass-making ovens.

How is a Glass Making Oven Utilized?

There are many preparations for the utilization of glass-making ovens. An experienced glass oven user doesn’t heat it right away.

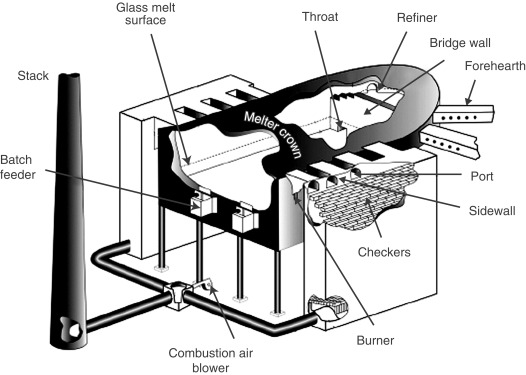

The utilization of glass-making ovens involves melting, refining, and regeneration of glass. Glass-making oven operators can’t interchange the process; otherwise, the output will be unsatisfactory.

Fuels for the glass ovens can also differ. Sometimes natural gases are used.

Electricity and oil fuels are also some alternatives to ignite it. The operator carefully puts fuel in the glass oven and makes sure that leaks are prevented all the time.

Once the oven is ignited, the melter is prepared. The melter is where the whole melting process takes place.

The melter is a basin near the gas burners and exhausts. It ensures that harmful and toxic fumes are going where they have to be.

Then, the glass will go through the refiner. The refiner is a tunnel with water at average temperatures and reaches the bridge wall.

The refiner will hold the glass to cool it evenly and slowly. It allows the glass to get a firmer structure and not break easily.

Both the melter and the refiner are also covered, so the heat doesn’t escape.

Optimal Conditions to Allow Glass Making Oven Work Properly

Materials that involve heating for processing have optimal conditions to work correctly. However, glass-making ovens are slightly different.

The optimal condition ensures that the fuel is enough, the oven is sturdy, and the exhausts are not clogged to make the glass-making oven work as intended. Other than that, there are not many conditions to make a glass oven work.

Glass oven operators keep the glass oven fuel in a different place, away from possible igniters.

It is what the operators do for the overall safety of their facility.

They also make sure that all parts of the glass-making oven are sturdy enough to handle high temperatures. Once a defective part of the oven is spotted, the glass-making process will not occur until it is fixed.

Even a single defective part can also pose a threat for all the glass oven operators. Still, most of the glass ovens’ design is simple.

The cleaning process is required for the glass-making oven’s exhausts. It is a must because the harmful smoke coming from the oven will go directly to the operator if there are no exhausts available.

Even though the smoke is minimal, exhausts are crucial in operating a glass-making oven.

How Glass Making Ovens are Maintained

Proper maintenance of glass-making ovens ensures that they will operate for a long time. That’s why it is a common practice for most glass-making oven operators.

Glass ovens are maintained by cleaning, checking for cracked or damaged parts and replacing them, and unclogging exhausts. The maintenance process is simple and can be done by most people.

When a glass-making oven is adequately maintained, it lasts for at least a decade with minimal repairs required. A glass-making oven is estimated to produce at least a thousand tons of glass in its whole operating time through the years.

Modern Usage of Glass Making Ovens

In modern times, glass-making ovens are still available in all glass-making facilities. The glass ovens will not go away any time soon as long as glass products are available in the market.

One example of glass oven usage is to make glass bottles, jars, and other glass containers. Even windows, mirrors, and glass furniture are made using glass-making ovens.

Also, most homes, facilities, and even vehicles rely on glasses. It is the reason why glass-making ovens will still be utilized in glass-related businesses in the foreseeable future.